A pump that is utilized for pumping a broad array of fluids is known as a peristaltic pump. If the product that is being pumped is abrasive or viscous, then it is the best solution. The only part that requires to be maintained is the tube or hose. Otherwise, it does not require much maintenance. Also, the pumps need no priming and include the capacity of pumping uphill as well. To be precise, it the ideal pump for the house brewer. Usually, these are utilized for pumping aggressive fluids as cross contamination cannot take place with uncovered pump components. Few typical applications incorporate pumping fluid via an infusion device.

The Way it Works

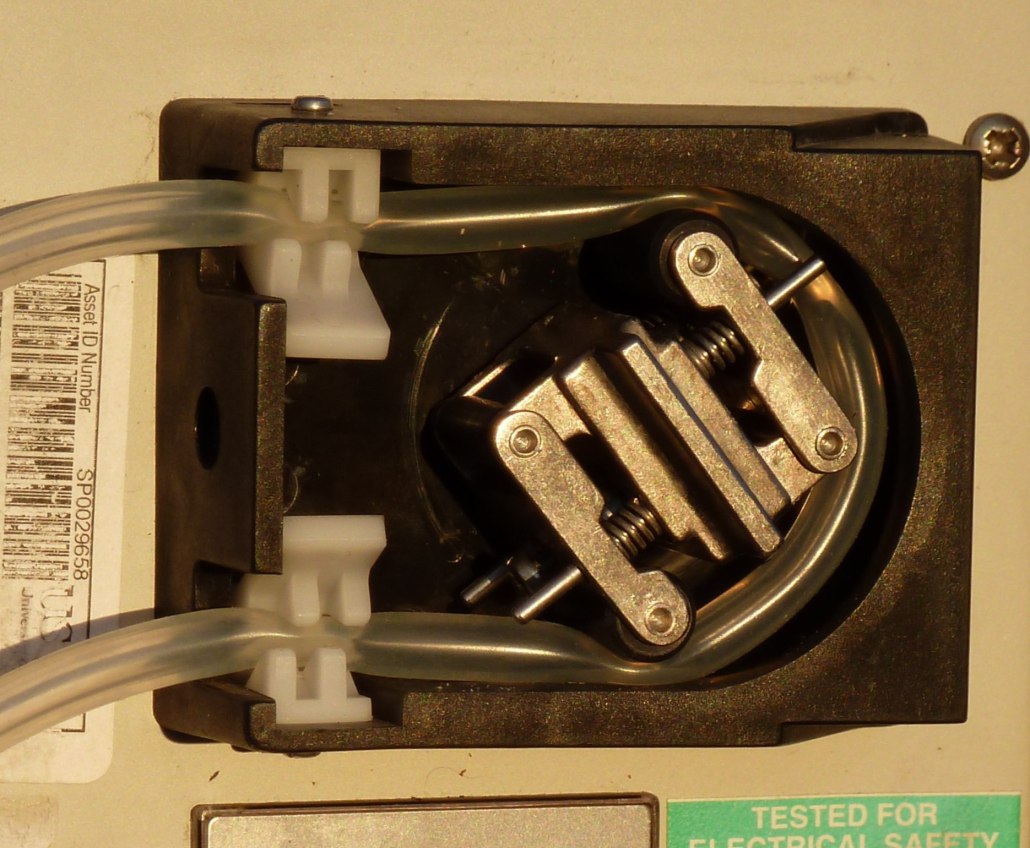

Depending on the alternating compression of the tube, the Peristaltic pumps draw the contents into the pipe, and it functions in the same way as your intestines and throats. A rotating roller passes next to the length of the tube and produces a seal between discharge side and suction of the pump by which it eradicates the product slip. A robust vacuum is shaped upon restitution of the tube that draws the product inside the pump. The product that is pumped never comes into touch with the moving parts and is completely contained within a sturdy extruded tube.

Noting the Specifications

There is a comprehensive array of Peristaltic pumps that can execute continuous and accurate pumping of all kinds of fluids. There are almost one to twenty-four channels. 0-5 V, 4-20 mA, 0-10 V are the speed control of the pump. The various tubing materials include Tygon, neoprene, silicone peroxide, pharMed, and many more. This equipment can also pump fluids that contain particles. Some of the vital options include a broad array of tube materials, drives, and controllers. Biotechnology, environmental, pharmaceutical, chemical, paint, food, and printing are few industries where the wide usage of this pump can be viewed.

Smooth Process of Sterilization

The area of the pump that is in touch with the fluid being forced is the core of the hose. This makes it easier for users to clean and sterilize the inside surfaces of the Peristaltic pumps. These pumps include no seals that help in preventing issues like leaks of acidic chemicals. These also include a tender pumping action that is perfect for sensitive products including broths. The life of the tube is not associated with the abrasive qualities of the product. The tube can only fail because of any chemical action.