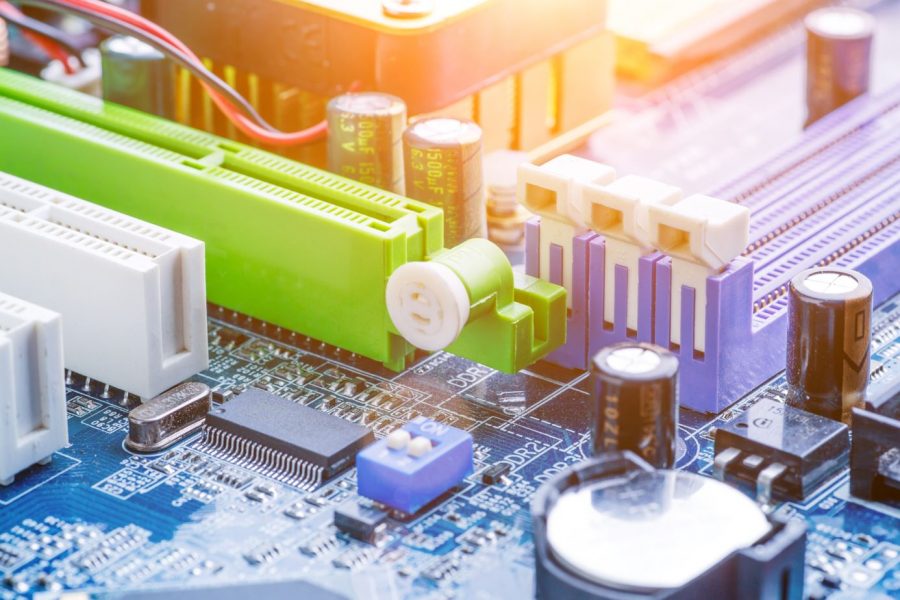

The printed circuit board, or PCB, has been the backbone of electrical engineering for decades. Multiple types of boards can be made depending on what they will be used for. The six major types are outlined below, along with their uses.

Types of Printed Circuit Boards:

Basic Board

This type of board is just what it sounds like. It is a board with a single circuit drawn on it and nothing else. This type of board does not have any components connected to the copper or connected, yet they are connected to the board via wire leads that come out of the edge where another component can be connected. Examples include breadboards, logic probes, and circuit breakers.

Single-Sided Board

As the name suggests, this type of board is a board with a single circuit drawn on it and nothing else. The board has copper only on one side of the board, and there are no components or connections to any of the copper on the other side. This makes it so that the board can be placed in a machine that ‘dunks’ it into a pool of solder, and then once the other side is submerged in the solder, that side will have components placed on it while being soldered by having their legs or leads dipped into the solder. The process of dunking it into the solder is called wave soldering. This type of board is the cheapest to make when in small quantities. Examples include breadboards, logic probes, circuit breakers, and antennas.

Double-Sided Board

This type of board has copper circuits on both sides of the board. Each side has separate connections that can be made or broken via switches or jumpers, which are moved into the position that allows the connection between two components on either side of the board. This type of board is often used in prototyping because it is cheap and quick. Examples include computers, TVs, radios, telephones, power supplies, etc.

Multi-Sided Board

This type of board has a single circuit drawn on all sides of the board. This makes it so that components can be added to either side or both sides without having to solder them from one side. Then, they are connected from the other side, where they have now been soldered onto the board. The connections between components are made by a machine that essentially drills through, wherever there is a connection to be made. This type of board is used in prototypes that are expected to have high production numbers. Examples include computers, TVs, radios, telephones, power supplies, etc.

Rigid-Flex Board

This type of board has two circuits drawn on it, one on each side of the board. It is then folded down in the middle to allow it to be flexed in two planes. This type of board is used in prototypes that are expected to have high production numbers. When flexing occurs, one circuit will always stay flat while having components attached on both sides, which can easily be connected by simply connecting the components on either side of the board.

Rigid-Foil Board

This type of board has two circuits drawn on it, one on each side of the board. It is then inflexed down so that if there were a planar surface, it would be flat and even across both sides. This type of board is used in prototypes expected to have high production numbers because it has the same properties as the rigid-flex. Still, instead of allowing flexibility by way of folding both sides down, this type of board allows flexibility via inflexing one side or another depending on which side needs to be made flat.

PCBs are circuit boards that make up the backbone of many modern electronics. They can be used in just about any type of electrical device, but they’re most commonly found in computers and other types of office equipment. If you want to learn more about this topic, there are plenty of websites or retailers with more information.