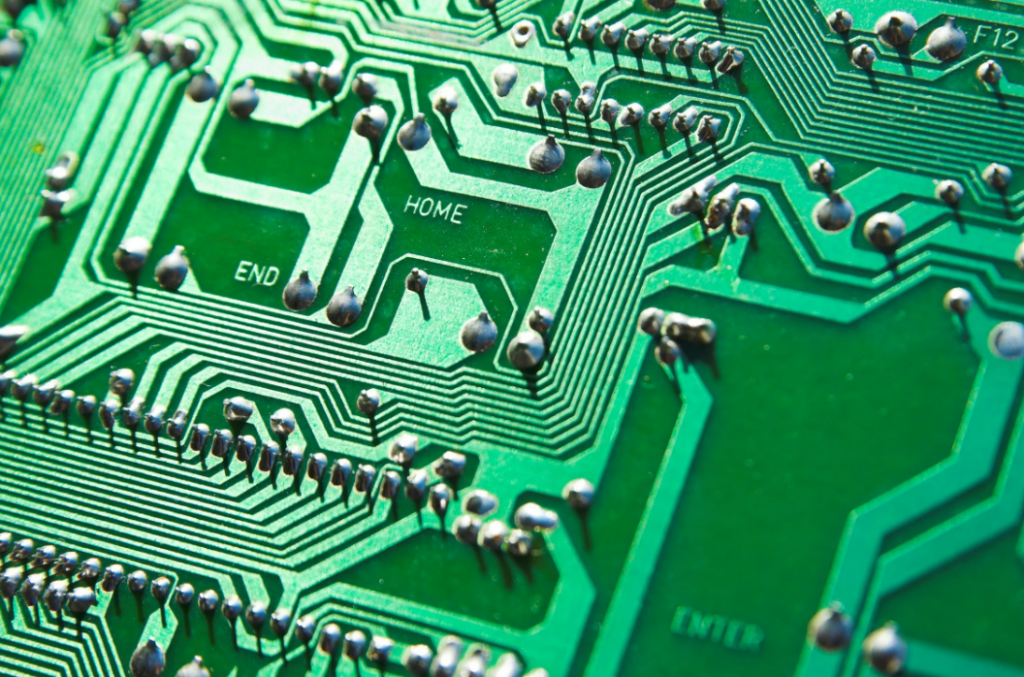

PCBs (printed control boards) are used for practically all electronic components. Although the design has been altered and improved since its introduction in 1936, there’s always room for more improvement. In fact, it’s something you could do. Here are a few methods to effectively improve the design of your PCB.

Seek the Advice of Others

Many companies produce PCBs across the globe. While they compete for your patronage it doesn’t stop a PCB manufacturer or two from giving you advice. Reach out to their employees or R&D team (with permission), and see if they have any suggestions that aren’t proprietary to their organization. Some PCB companies, like Advanced Circuits, offer consulting and design services specifically to help clients, so they can also be an excellent resource for you.

Create a Ground Plane

The ground plane is one of the first things you must consider when designing a PCB. It shouldn’t be removed to improve the board’s efficiency. Overall, that would achieve the opposite, for it has the potential to damage the PCB itself as well as nearby components. Create the plane to minimize voltage drops or surges.

On top of this, keep the power circuits separate from the control ground. The former creates currents that cause interference in the latter’s circuits. Review your board and tie the two together near the start of a supply path.

Properly Space the Components

PCBs have become smaller over time. Yet, there’s still enough space between its components to allow for some breathing room. Improve the design of your PCB by doing the same. It’s a good idea to utilize a design application to create a schematic of the object. This way, you have a larger picture of the board to minimize crowding issues.

Ensure Proper Orientation

If you’re designing a board from scratch—in other words, constructing the circuit profile—you must consider the proper orientation of the components. The reason is all of them come with pins structured in numerical order.

Therefore, the #1 pin goes into the upper left-hand corner of a particular board space. When this is reversed you not only cause potential problems once installed but other components don’t fit as well. Using the design application mentioned above, make sure to note the uniform orientation so soldering and inspection become easier.

The above-mentioned items are a few of the tasks required to effectively improve the design of your PCB. In the end, you must perform further research on the topic to understand the basics of construction. Once you do that, you can apply the suggestions here for a lean circuit board.